Welcome to Our Company -

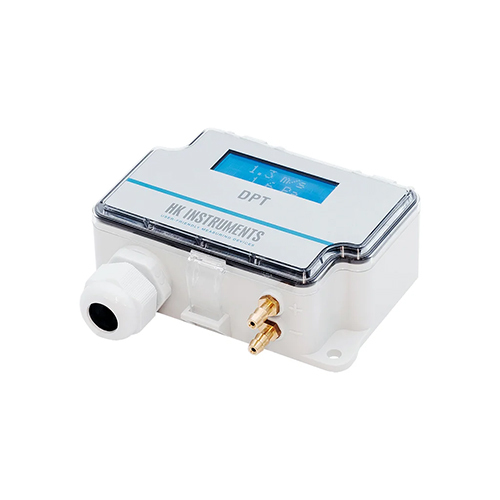

Differential Pressure Transmitter 982R

Product Details:

- Bourdon Tube Not applicable (uses diaphragm sensor)

- Thread G1/4 (BSP), optional NPT thread

- Sensor Type Capacitive differential pressure sensor

- Grade Industrial

- Outer Size Approx. 120 mm diameter

- Display Analog dial gauge

- Seal Material NBR rubber

X

Differential Pressure Transmitter 982R Product Specifications

- Die-cast aluminum housing with plastic front

- Not applicable (uses diaphragm sensor)

- Approx. 110 mm viewing area

- 1.5% FS

- Panel or wall mount

- 0-1000 Pa (custom ranges available)

- Pressure measurement

- Analog dial gauge

- Mounting brackets, screws, instruction manual

- Black anodized aluminum

- NBR rubber

- Air and non-corrosive gases

- 120 mm nominal

- Capacitive differential pressure sensor

- White painted aluminum

- Industrial

- Approx. 120 mm diameter

- G1/4 (BSP), optional NPT thread

- Powder-coated, corrosion-resistant finish

- IP54

- Not required (mechanical)

- <2 seconds

- Approx. 450 grams

- -10C to +60C

- Die-cast aluminum

- Two pipe connections for high and low pressure

- CE marked

- External adjustment screw

- Up to 200% of full scale

Product Description

Applications :

- Building automation, air conditioning systems and clean room monitoring

- Valve and flap control

- Filter, ventilator and blower monitoring

- Control of air flows

Technical Data :

- Setting ranges:

Type Pressure ranges between Overload capacity 982R.623 0 and 100 Pa 60 kPa 982R.633 0 and 250 Pa 60 kPa 982R.643 0 and 500 Pa 75 kPa 982R.653 0 and 1 kPa 75 kPa 982R.663 0 and 2,5 kPa 85 kPa 982R.673 0 and 5 kPa 85 kPa 982R.683 0 and 10 kPa 85 kPa 982R.693 0 and 25 kPa 135 kPa 982R.6A3 0 and 50 kPa 200 kPa 982R.6B3 0 and 100 kPa 200 kPa

- Temperature range:

Working and Storage temperature from 20C to +70C

- Process connection:

6,0 mm hose connection

- Supply voltage:

3-wire type:

18 to 30 VAC / VDC

2-wire type:

18 to 30 VDC

- Output signal:

- 3-wire type:

- 0 10 VDC or

- 4 20 mA

- 2-wire type:

- 4 20 mA

- Electrical connection:

Spring terminals for wires and leads up to 1.5 mm2 or circular connectors M12 / 4-pole

- Protection class:

IP54 with protection cover acc. to EN 60529

Reliable Differential Pressure Measurement

Engineered for industrial applications, the Differential Pressure Transmitter 982R ensures dependable performance in monitoring differential pressure of air and non-corrosive gases. Its capacitive sensor delivers accurate analog readings, while an IP54 die-cast aluminum enclosure protects against dust and spray, making it suitable for challenging environments. Ease of installation is assured with mounting brackets and customizable thread options.

User-Friendly Installation and Maintenance

The 982R simplifies setup and ongoing use with clear analog display, external zero adjustment screw, and included instructional manual. Its panel or wall mount design, coupled with mounting accessories, supports flexible placement in diverse industrial settings. The absence of electrical power requirements enhances safety and efficiency during both operation and maintenance.

FAQ's of Differential Pressure Transmitter 982R:

Q: How is the 982R differential pressure transmitter installed?

A: The 982R can be installed using the provided mounting brackets and screws, either on a panel or a wall. Connections for high and low pressure are made via G1/4 (BSP) threads, with an optional NPT version available. Detailed instructions are included in the manual for secure and straightforward setup.Q: What process media can the 982R measure pressure for?

A: This transmitter is designed to measure the differential pressure of air and non-corrosive gases, making it well-suited for HVAC systems, cleanrooms, filter monitoring, and other industrial applications where aggressive media are not present.Q: When is it beneficial to use a transmitter with no power supply requirement?

A: Using a mechanical pressure transmitter like the 982R is advantageous in locations where electrical power is limited or prohibited. It enhances operational safety, ensures continuous measurement during power outages, and reduces maintenance complexity associated with electrical components.Q: Where can the 982R transmitter be mounted in industrial environments?

A: The 982R's versatile design allows it to be mounted on a panel or a wall, enabling flexible placement in control rooms, equipment panels, or directly in process areas where differential pressure readings are required.Q: What is the process for zero adjustment on the 982R?

A: The 982R features an external adjustment screw that allows users to perform zero point calibration without dismantling the device. This straightforward process ensures ongoing accuracy and minimizes downtime during routine maintenance.Q: How does the ingress protection rating (IP54) benefit the device's usage?

A: With an IP54 rating, the 982R is safeguarded against dust ingress and water splashes from any direction. This ensures reliable operation in industrial settings where exposure to particulate matter or moisture may occur.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS