Welcome to Our Company -

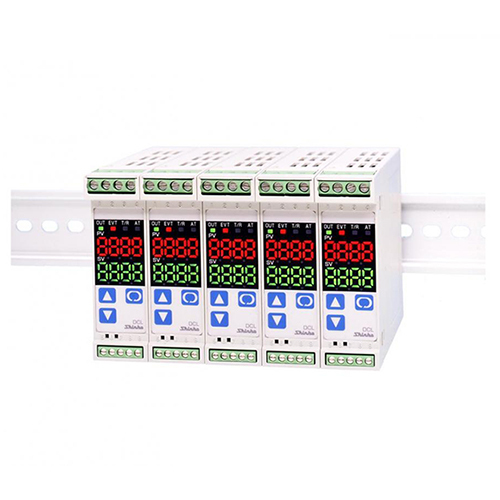

DIN Rail Mounted Indicating Controllers DCL-33A series

Product Details:

- Connection Screw terminals

- Accuracy 0.2% of span

- Function Indicating Controller for DIN Rail Mounting

- Size 22.5 x 75 mm

X

DIN Rail Mounted Indicating Controllers DCL-33A series Product Specifications

- 22.5 x 75 mm

- Indicating Controller for DIN Rail Mounting

- 0.2% of span

- Screw terminals

- 4 times per second

- Relay, SSR, Current (4-20mA)

- Configurable, up to 2 alarms

- User adjustable

- 90-270V AC/DC or 24V AC/DC

- 22.5 (W) x 75 (H) x 105 (D) mm

- Thermocouple, RTD, mV, V, mA

- Digital push-buttons

- LED digital display

- IP20 (front panel)

- 0°C to 50°C

- DIN rail 35 mm

- Approx 170 g

Product Description

Heater burnout alarm, Serial communication (RS-485),Heating/Cooling control, Set value memory external selection, External setting input| Spec | |

|---|---|

| Input | Thermocouple, RTD, Direct curren, DC voltage |

| Accuracy | Thermocouple: Within ±0.2 % of each input span 1 digit RTD: Within ±0.1 % of each input span 1 digit Direct current, DC voltage: Within 0.2 % of each input span 1digit |

| Sampling period | 125 ms |

| Control action | Auto-tuning PID, PI, PD, P, ON/OFF |

| Control output | Relay contact, Non-contact voltage, Direct current |

| Supply voltage | 100 to 240V AC 50/60Hz, 24V AC/DC 50/60Hz |

| Options |

| Features | |

|---|---|

| Compact 22.5mm(W) x 75mm(H) x 100mm(D) | Controller can be easily installed on a DIN rail inside the control panel. |

| Multi-input, High sampling speed | Total 18 types of input and 125 ms of high sampling speed allow you to deal with various processes; Thermocouple (10 types), RTD (2 types), Direct current(2 types), DC voltage (4 types ) |

| Modbus protocol available | Shinko protocol, Modbus protocol (ASCII, RTU) are selectable. Monitoring software is also provided. |

Flexible Input Selection

The DCL-33A supports a wide range of input signals such as thermocouples, RTDs, voltage, and current. This flexibility makes it suitable for monitoring diverse process parameters, enabling integration into various industrial setups without additional converters.

User-Friendly Operation

Configured with digital push-buttons, the controller simplifies the setup and adjustment process. Users can easily calibrate settings, configure alarms, and adjust hysteresis directly from the front panel, minimizing downtime and ensuring smooth operation.

Reliable Performance & Safety

Operating reliably within 0C to 50C, the DCL-33A includes a robust IP20 front panel for protection against dust and accidental contact. Its high sampling rate and adjustable hysteresis guarantee precise, stable readings and response, supporting critical control tasks.

FAQ's of DIN Rail Mounted Indicating Controllers DCL-33A series:

Q: How do I mount the DCL-33A Indicating Controller onto a DIN rail?

A: You can mount the DCL-33A on a standard 35 mm DIN rail using its integrated rear clip. Simply snap the device onto the rail, ensuring it is secure and positioned for easy access to the display and push-buttons.Q: What types of input signals are compatible with the DCL-33A controller?

A: This controller accepts thermocouple, RTD, mV, V, and mA input signals, allowing for broad application in temperature, process, and voltage/current measurement scenarios.Q: When should I use the configurable alarm outputs?

A: Configurable alarm outputs are useful for triggering alerts when measured parameters go outside preset thresholds. This feature is essential for safety applications, process monitoring, and preventative maintenance.Q: Where is the DCL-33A best utilized within an industrial setting?

A: The DCL-33A fits perfectly in control panels, distribution boards, and process automation lines. Its DIN rail mounting allows easy integration into any standard enclosure in manufacturing, chemical, or packaging industries.Q: What is the process for adjusting the hysteresis and control settings?

A: Adjustments are made using the front panel push-buttons. Hysteresis and other control settings can be configured digitally, following the instructions in the user manual to optimize system stability and performance.Q: How does the LED digital display benefit daily operations?

A: The bright LED display provides immediate, accurate process readings, minimizing errors and allowing operators to monitor conditions at a glance. This facilitates quick diagnostics and timely responses during operation.Q: What are the primary advantages of choosing the DCL-33A Indicating Controller?

A: Key advantages include its versatile input compatibility, easy installation, precise measurement accuracy (0.2% of span), and user-friendly configuration. These features together ensure reliable process control and efficient maintenance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free