Welcome to Our Company -

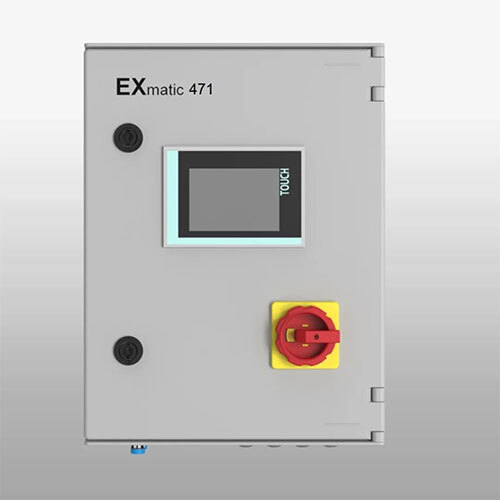

EXmatic 471

Product Details:

- Humidity % Up to 85% RH

- Connectivity Type Relay Output, Digital I/O

- Resolution 1 Count

- Equipment Type Automatic Liquid Filling Machine Controller

- Frequency 50 Hz

- Measurement Range 0-99999 Counts

- Sensor Type Compatible with Magnetic/Optical Sensors

X

EXmatic 471 Product Specifications

- Up to 85% RH

- Relay Output, Digital I/O

- 0-99999 Counts

- 230 V AC 10%, 50 Hz

- 1 Count

- ABS Plastic Housing

- 1% of FS

- 7 Segment LED Display

- 0-99999 Counts

- 10 VA max.

- Automatic Liquid Filling Machine Controller

- 50 Hz

- 0C to 50C

- As per flow sensor specification

- Compatible with Magnetic/Optical Sensors

- As per customer requirement

- 2 Relay Outputs

- Indoor Only

- CE Certified

- Approx. 1.2 kg

- Front Keypad

- 96 x 96 x 110 mm

- Panel Mounting

- IP54

- <1 second

- Yes (Visual & Audible)

Product Description

Specification

| Voltage supply: | 24 V DC / 30 VA |

| Air supply: | compressed air 6 bar |

| Input for ext. trigger: | 24 V DC internal power supply for potentialfree contact |

| Current consumption: | 1,6 A max. |

| Output ext. relays: | 24 V DC max. 250 mA |

| Output pump: | 24 V DC max. 250 mA |

| Output alarm contacts: | 24 V DC max. 100 mA |

| Housing material: | glass-reinforced plastic or stainless steel |

| Housing dimensions: | 300 x 400 x 200 mm |

| Ambient temperature: | 0+55 C |

| Type of protection: | IP54 |

User-Centric Design for Reliable Operation

Designed for indoor use, the EXmatic 471 prioritizes both reliability and operator convenience through its front keypad programming, audible/visual alarms, and bright 7-segment LED display. Its panel mounting and IP54 protection ensure seamless integration into control panels, providing sturdy defense against dust and limited water exposure. System status is always visible, allowing for quick and effective responses during operation.

Comprehensive Monitoring and Precision Control

Equipped with two relay outputs, the EXmatic 471 enables precise actuation in automated liquid filling applications. The fast response time of less than one second and a resolution of 1 count assure accurate measurement and control, accommodating up to 99,999 counts. With compatibility for both magnetic and optical sensors, it is adaptable to diverse filling setups.

Efficient Compliance and Adaptability

The controller meets CE certification standards, guaranteeing dependable operation and safety in industrial environments. Capable of handling variable flow rates and count capacities per customer requirements, its ABS plastic build ensures longevity and resilience. The 230 V AC10% power supply with minimal energy consumption supports sustainability and aligns with global operational standards.

FAQs of EXmatic 471:

Q: How does the EXmatic 471 controller integrate into existing liquid filling systems?

A: Integration is straightforward due to its panel mounting design and standard relay outputs. The front keypad makes programming parameters easy, and compatibility with magnetic or optical sensors ensures seamless connection with most filling setups.Q: What benefits does the IP54 enclosure provide for indoor environments?

A: The IP54-rated enclosure offers protection against dust ingress and limited water splashes, enhancing the controllers durability and reliability in typical indoor industrial settings.Q: When should I use the visual and audible alarm features?

A: These alarms activate under abnormal operating conditions or preset thresholds, enabling timely intervention by operators and reducing risks of overfilling or system faults.Q: Where is the EXmatic 471 best suited for installation?

A: This controller is optimized for indoor installation within control panels in production facilities such as manufacturing units, bottling plants, or chemical processing stations.Q: What is the programming process for configuring this controller?

A: Programming is accomplished via the intuitive front keypad. Users can set operational parameters, alarm thresholds, and relay functions directly, without needing external devices.Q: How can the controller benefit distributors and exporters in India?

A: As a CE certified, versatile, and reliable device, the EXmatic 471 accommodates various customer needs, ensuring ease of distribution, installation, and after-sales support across India.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS