Welcome to Our Company -

EXtract 825

Product Details:

- Mounting Type Tabletop

- Specimen Size 100 mm 100 mm

- Number of Specimens Up to 3 at a time

- Automation Grade Semi-automatic

- Accuracy 0.5% F.S.

- Operating Voltage 220V AC

- Interface Type RS232 / USB

X

EXtract 825 Product Specifications

- 2 seconds

- 65 kg

- Automatic peak capture, Overload protection, Real-time data output

- 0-500 N

- Laboratory and industrial settings

- 0.01 Nm

- Torque testing of bottle caps and closure systems

- 0-20 Nm

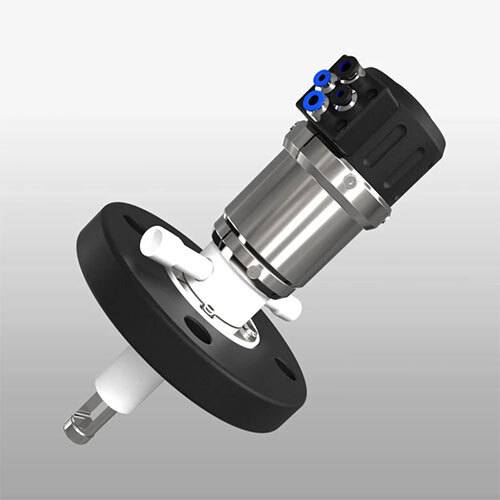

- Bottle Cap Torque Tester

- 0.40.7 MPa

- Digital LCD display

- HRC 58-62 (Fixture)

- Adjustable as per standards

- Room temperature (1040C)

- 20%70% RH

- 6 mm

- AC 220V, 50 Hz

- 50 Hz

- 350 mm

- 300 mm max

- 400 mm

- Microprocessor based control

- Up to 3 at a time

- 100 mm 100 mm

- 0.5% F.S.

- Semi-automatic

- Tabletop

- 10-500 mm/min adjustable

- 220V AC

- RS232 / USB

- Industrial blue-grey

- Stepper motor drive

- Best under 1000 Lux

- Powder-coated metal

- Proprietary PC software

- Up to 50 test results

- Real-time & batch export

- Emergency stop, Over-travel limit switch

- High precision torque sensor

- Manual / Automatic

Product Description

Advantage

- Robust design, integrated PTFE scraper

- Usable for DN25 welding socket

- Extension of sensor-lifetime and reducing of maintenance efforts

- Automatic safety lock while sensor is removed

- Usable in ATEX-areas

- Immersion length 70mm

- Up to 10 bar and 140 C

- PP / PVDF or PEEK

- Can be fully automated with electropneumatic control unit EXmatic 470

- Drive unit free of maintenance

Specification

| Process pressure: | 010 bar |

| Process temperature: | -10140 C |

| Ambient temperature: | -1070 C |

| Immersion length: | 70 mm |

| O-ring position: | 25 mm |

| Sensors: | 225mm 12 PG 13.5 |

| Materials: | PP, PVDF, PEEK |

| Sealings: | EPDM, FPM (Viton), FFKM (Kalrez) |

| Process connection: | G1 1/4 (DN25) |

| Cleaning ports: | G1/8, G1/4, FNPT1/4 |

| Operating power: | compressed air 4..6 bar |

| Limit switches: | pneumatic, integrated |

Precision in Torque Testing

The EXtract 825 is engineered to deliver reliable torque measurements for bottle caps and closures, essential for quality assurance in production lines and research labs. Its high-precision torque sensor, combined with an adjustable measuring range of 0-20 Nm, ensures consistent, repeatable results for a variety of closure types.

User-Friendly Operation

Equipped with a digital LCD display, manual or automatic calibration, and a straightforward interface, the EXtract 825 streamlines user interaction. The automatic peak capture and real-time output functions simplify result recording, while safety mechanisms like emergency stop and overload protection promote safe use.

Efficient Data Management

With the ability to store up to 50 test results and compatibility with proprietary PC software, the device supports both real-time and batch data export via RS232 or USB. This facilitates thorough analysis, record keeping, and easy integration with existing laboratory workflows.

FAQ's of EXtract 825:

Q: How does the EXtract 825 capture and store test results?

A: The EXtract 825 utilizes a digital LCD display with memory storage for up to 50 test results. Users can export data in real time or as batch files via RS232 or USB ports, making it ideal for efficient data management and reporting.Q: What benefits does the microprocessor-based control offer?

A: Microprocessor-based control ensures precise test execution, automated adjustments, and minimal manual intervention, enhancing accuracy and reducing operational errors. This improves repeatability and reliability in torque testing of bottle caps.Q: When should I perform calibration on the EXtract 825?

A: Calibration can be conducted manually or automatically, depending on your application needs or standard operating protocols. Regular calibration, especially after long periods of inactivity or significant usage, ensures that measurement accuracy is maintained.Q: Where can the EXtract 825 be used effectively?

A: The device is tailored for laboratories and industrial settings where bottle cap torque testing is needed. Its sturdy, powder-coated metal body and safety features support frequent use in production, quality control, and research environments.Q: What is the process for conducting a torque test on bottle caps?

A: To perform a test, mount up to three bottle cap specimens measuring 100 mm 100 mm within the fixtures, set the desired parameters via the digital interface, and initiate the test. The machine will measure, display, and store the torque results accordingly.Q: How does the EXtract 825 ensure user safety during operation?

A: The machine is equipped with several safety mechanisms, including an emergency stop button and over-travel limit switches, as well as overload protection, safeguarding both users and the unit during testing activities.Q: What are the usage requirements for optimal performance?

A: For best results, operate the EXtract 825 under ambient light conditions below 1000 Lux, maintain a room temperature between 10-40C, and a humidity range of 20%-70% RH. Adhering to these ensures stable, precise measurements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free