Welcome to Our Company -

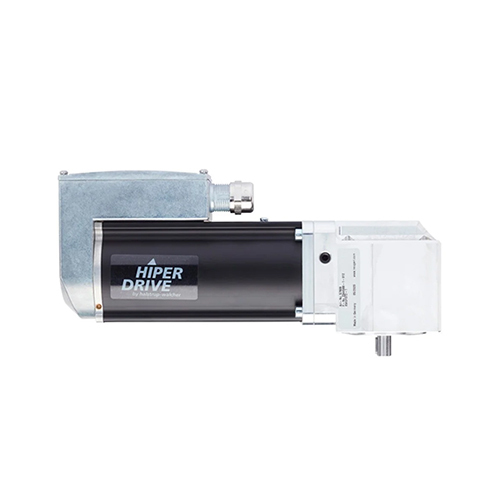

Positioning system HIPERDRIVE HDA 70

Product Details:

- Protection IP54

- Application Media Positioning and Automation Equipment

- Current Range 0-5 A

- Diameter 70 mm

- Sensor Type Rotary Encoder

- Resolution 0.01 mm

- Frequency 50/60 Hz

X

Positioning system HIPERDRIVE HDA 70 Product Specifications

- 0 to 9,999 mm

- RS232/RS485, Ethernet (optional)

- Non-condensing up to 85%

- Digital LED Display

- 230 V AC, 50/60 Hz

- High-Grade Aluminum Alloy

- Up to 500 kg Load

- 0C to +50C

- 50/60 Hz

- 0.01 mm

- 15 VA

- 0-9999 mm

- 70 mm

- Rotary Encoder

- 0.05 mm

- 0-5 A

- Positioning and Automation Equipment

- IP54

- PG9

- PLC Compatible

- Integrated LEDs for Status

- 24 V DC Logic

- CE Certified

- 185 mm x 118 mm x 104 mm

- Positioning System

- 2.5 kg

- 20 Nm (maximum)

- Manual/Automatic

- Horizontal/Vertical

Product Description

Advantages for the user:

- Simple bus structure as only one bus node is required for up to 8 drives.

- Simplified cabling as only one cable is used for the power supply and bus signal to the drive. This saves costs by reducing the number of cables and bus nodes required.

Design

- Longitudinal or horizontal construction (horizontal with bevel gear: radial type)

Nominal torque/ nominal rated speed:

- 15 Nm / 27 rpm

Data interface

- PROFIBUS DP, PROFINET, EtherCAT, EtherNet/IP, RS 485 (for control via Hub)

Positioning accuracy

- ± 1°

Output shaft

- 10 mm solid shaft with feather key (axial or radial)

- 10 / 12 mm hollow shaft (only radial, with bevel gear)

Positioning range

- 32,000 rotations, not subject to mechanical limits

Supply voltage

- 24 VDC

Protection class

- IP 65

Precision and Reliability for Automation

Engineered for high-precision tasks, the HIPERDRIVE HDA 70 delivers 0.05 mm accuracy, ensuring exact positioning even in demanding industrial settings. Its sturdy aluminum alloy build, IP54 protection, and 0-9999 mm range make it a dependable choice for a variety of automation applications.

Versatile Integration Options

Seamlessly integrate the HIPERDRIVE HDA 70 into existing systems with PLC-compatible signals and multiple connectivity options including RS232, RS485, and optional Ethernet. The system accommodates both manual and automatic operation, providing flexibility in deployment.

User-Centric Controls and Feedback

The system features intuitive controls, a digital LED display for clear readouts, and integrated LED status indicators for quick diagnostics. With a mounting position that can be adjusted horizontally or vertically, installation is straightforward for diverse industrial layouts.

FAQ's of Positioning system HIPERDRIVE HDA 70:

Q: How does the HIPERDRIVE HDA 70 achieve high precision in positioning tasks?

A: The system utilizes a rotary encoder sensor and offers a fine resolution of 0.01 mm with an overall accuracy of 0.05 mm. This ensures extremely precise positioning, which is essential for advanced automation and positioning applications.Q: What are the recommended applications for the HIPERDRIVE HDA 70 positioning system?

A: It is ideal for use in positioning and automation equipment, especially where precise movement and feedback are required, such as assembly lines, robotics integration, and automated storage systems.Q: When should I use manual versus automatic operation mode?

A: Manual mode is recommended during setup, calibration, or in situations where operator intervention is needed. Automatic mode is best suited for continuous or repetitive processes controlled via PLC integration.Q: Where can the HIPERDRIVE HDA 70 be installed within an industrial setup?

A: Thanks to its compact dimensions and mounting flexibility, it can be installed both horizontally and vertically, making it suitable for a wide range of machine environments and industrial enclosures.Q: What is the process for connecting the positioning system to a PLC?

A: The system provides PLC-compatible control logic (24 V DC) and supports RS232, RS485, or optional Ethernet interfaces for integration. Simply connect the appropriate communication cable and configure the PLC according to the supplied documentation.Q: How does the diagnostic feedback via integrated LEDs benefit users?

A: The integrated LEDs provide real-time visual status updates, enabling rapid diagnostics and reducing downtime. Operators can swiftly identify issues such as operational errors or communication faults.Q: What are the main benefits of choosing HIPERDRIVE HDA 70 for automation projects?

A: Key benefits include high precision, strong load capacity (up to 500 kg), flexible connectivity, durability (IP54 protection), and compliance with CE standards, making it a reliable and future-proof solution for advanced industrial automation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free