Welcome to Our Company -

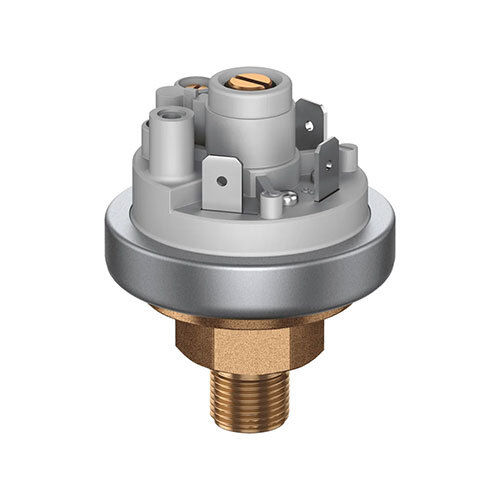

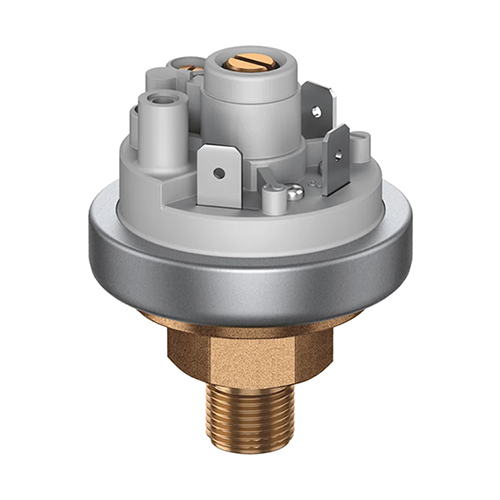

Pressure switch 901 EX factory-set

Product Details:

- Accuracy 2% of full scale

- Pressure Factory-set; pressure range options up to 400 bar

- Connection G 1/4 (female) process connection

- Function Factory-set pressure switch for monitoring and controlling pressure in hazardous areas (EX-certified)

- Size Compact; typically suitable for panel mounting (refer to image for exact dimensions)

X

Pressure switch 901 EX factory-set Product Specifications

- Factory-set; pressure range options up to 400 bar

- Compact; typically suitable for panel mounting (refer to image for exact dimensions)

- 2% of full scale

- Factory-set pressure switch for monitoring and controlling pressure in hazardous areas (EX-certified)

- G 1/4 (female) process connection

- Electromechanical micro-switch

- DIN rail or panel mount

- Anodized aluminium, corrosion-resistant

- Terminal block inside enclosure

- 5A at 250 VAC

- IP65 (dust and low-pressure water jets)

- 901 EX

- -20°C to +80°C

- NO/NC status indicator on micro-switch

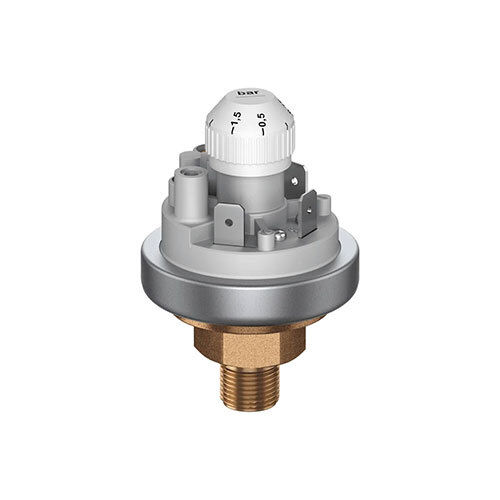

- Non-adjustable, factory set

Product Description

Applications :

- Wastewater technology

- liquid level measurement

- pump control

- medical technology

- and many more

Technical Data :

- Setting ranges:

Typ Factory-set switching points between Maximum positive working pressure

Standard/extended901.1x Ex 5 mbar and 200 mbar

200 mbar and 1.000 mbar0,5 / 4 bar

1 / 4 bar901.41Ex 500 mbar and 3.000 mbar 10 bar 901.51Ex 1,0 bar and 12 bar 25 bar 901.2x Ex -5 mbar and -200 mbar

-200 mbar and -900 mbar0,5 / 4 bar

1 / 4 bar901.30 Ex 5 mbar and 50 mbar 100 mbar

- Temperature range:

Temperature of media and ambient temperature from -20°C to 85°C

Storage temperature: -40° C bis +85° C

- Diaphragm material:

Depending on media NBR, Silicone, FKM (Viton®), EPDM. For 901.30 Silicone, others upon request.

- Pressure connection:

Material: PA, PVDF, Brass, Stainless steel

Hose nipple: 5,0mm, 6,5mm, 10,0mm

Thread: M10x1, G1/8, G1/4, G1/2

- Electrical rating:

24 VDC/100 mA

30 VDC/45 mA

- Electrical connection:

AMP flat plug 6.3 x 0.8 mm according to DIN 46244 or push-on screw terminals

- Protection class:

IP 54 (with cover 6371)

Rugged Hazardous Area Design

The 901 EX pressure switch is EX-certified, making it an excellent choice for hazardous environments where safe and dependable pressure monitoring is essential. Its anodized aluminium housing resists corrosion and its IP65 enclosure provides reliable protection against dust and water jets, further enhancing durability and safe operation in challenging conditions.

Effortless Installation and Maintenance

Equipped with a terminal block inside the enclosure and a compact form factor, the 901 EX supports both DIN rail and panel mounting. This design allows for straightforward installation, minimizing downtime and complexity. The factory-set, non-adjustable mechanism ensures consistent operation without the need for on-site calibration, streamlining maintenance.

Accurate Monitoring for Industrial Applications

With an accuracy of 2% of full scale and a clear NO/NC status indicator, the 901 EX delivers trustworthy feedback for pressure monitoring and control. This makes it suitable for a variety of industrial applications where precision and reliable status indication are critical, especially in hazardous locations.

FAQ's of Pressure switch 901 EX factory-set:

Q: How does the factory-set 901 EX pressure switch operate?

A: The 901 EX works by automatically switching its contacts when a pre-set pressure threshold is reached. Since it is factory-set, users cannot adjust the pressure setting on-site, ensuring reliable and consistent performance as calibrated.Q: What are the main benefits of using the 901 EX pressure switch in hazardous areas?

A: The 901 EX is EX-certified for use in hazardous areas, offers reliable IP65 protection, and its anodized aluminium housing resists corrosion. It provides precise pressure control and status indication, ensuring safety and operational efficiency in demanding industrial environments.Q: When should I choose a factory-set, non-adjustable pressure switch like the 901 EX?

A: The 901 EX is ideal when consistent, tamper-proof pressure settings are required, such as in standardized control systems or hazardous zone applications where field adjustment could compromise safety or reliability.Q: Where can the 901 EX pressure switch be installed?

A: This switch can be installed on either DIN rails or panels, making it versatile for integration into a wide range of industrial control cabinets or enclosures, especially where compact and EX-certified devices are needed.Q: What process connection is provided and what pressure ranges are available?

A: The 901 EX features a G 1/4 (female) process connection and is available with factory-set pressure thresholds up to 400 bar. Users should specify the required pressure range upon ordering as it cannot be adjusted in the field.Q: How does the NO/NC status indicator on the micro-switch assist in operation?

A: The clearly visible NO/NC status indicator provides immediate feedback on the switch position, allowing for straightforward verification of the actuated state during operation or maintenance checks.Q: What is the typical usage process for the 901 EX in an industrial setup?

A: After installation and wiring, the 901 EX continuously monitors system pressure. On reaching its factory-set point, it actuates the internal micro-switch, changing the output contact state. The integrated indicator provides visual confirmation of switching, helping operators monitor system status.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free