Welcome to Our Company -

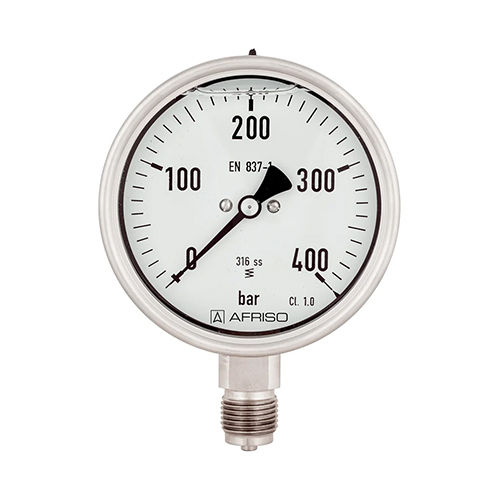

Standard Capsule Pressure Gauges Type D4

Product Details:

- Thread 1/2 BSP

- Grade Industrial

- Sensor Type Capsule Element

- Bourdon Tube Not Applicable (Capsule Type)

- Outer Size 110 mm

- Display Analog Dial

- Seal Material Buna-N / Neoprene

X

Standard Capsule Pressure Gauges Type D4 Product Specifications

- 110 mm

- 1.6% F.S.

- Stainless Steel (SS 304/316)

- Matt / Glossy

- Bottom / Back

- Analog Dial

- Aluminum, black finish

- Buna-N / Neoprene

- 100 mm

- 1/2 BSP

- Machined

- Industrial

- Capsule Element

- Low Pressure (Gas / Air)

- Mounting Bracket, Calibration Certificate

- Not Applicable (Capsule Type)

- 100 mm

- Aluminum with printed scale

- 0 to 600 mmWC

- Bottom / Center Back

- Brass / SS

- Panel / Surface / Direct

- IP52 / IP65 (Optional)

- 1 Piece

- Stainless Steel / Mild Steel

- Non-corrosive Gases

- Clear Glass / Shatterproof Glass

- -20°C to +70°C

Product Description

TypeD4

Nominal size100

Accuracy class (EN 837-3/6)1,6

Ranges (EN 837-3/5)See ordering table

Application area

Static load:Full scale value

Dynamic load:0.9 x full scale value

Overload safety:1.3 x full scale value

Operating temperature range

Medium:Max. 60 °C

Ambient:-20/+60 °C

Temperature performanceIndication error when the temperature of the measuring system deviates from the normal temperature of 20 °C:

at rising temperature approx. ± 0.6 %/10 K

falling temperature approx. ± 0.6 %/10 K

of full scale value

at rising temperature approx. ± 0.6 %/10 K

falling temperature approx. ± 0.6 %/10 K

of full scale value

Degree of protection

NG 100:IP 54 (EN 60529)

Standard design

ConnectionBrass, bottom

Measuring elementCapsule element, CuBe alloy

MovementBrass

Zero correctionFrom the front

SealNBR (Perbunan)

DialAluminium, white

Scaling black

Scaling black

PointerAluminium, black

HousingStainless steel 304

Bayonet type bezelStainless steel 304

Window

D401:Instrument glass

Options

- Overpressure and underpressure safety 10 x FSD

- Back flange

- Panel mounting bezel, with window, plastic

- 3-hole fixing, panel mounting bezel with window, plastic

- Damping screw

- Reference pointer

- Special scales

- Other process connections

Durable Construction with Flexible Configurations

The Type D4 capsule pressure gauges are engineered using high-quality stainless steel (SS 304/316) or mild steel, with options for both matt and glossy finishes. They accommodate a range of mounting styles-panel, surface, or direct-and can be fitted with either clear or shatterproof glass for added protection.

Precision Measurement for Low-Pressure Gases

Designed primarily for measuring low-pressure non-corrosive gases or air, these gauges operate efficiently within a scale range of 0 to 600 mmWC. Their capsule element sensor provides reliable and repeatable analog dial readings with a commendable accuracy of 1.6% F.S. under ambient temperatures from -20C to +70C.

Comprehensive Accessories and Certification

Each gauge is supplied with a mounting bracket and a calibration certificate, ensuring straightforward installation and verified measurement accuracy. With a minimum order quantity of just one piece, this solution is accessible for both small and large-scale industrial requirements.

FAQ's of Standard Capsule Pressure Gauges Type D4:

Q: How do I choose between the stainless steel and mild steel case material for the D4 capsule pressure gauge?

A: The choice depends on your application's environment. Stainless steel cases are highly resistant to corrosion, making them suitable for humid or challenging conditions, while mild steel is ideal for general indoor use where high corrosion resistance is not required.Q: What types of gases can the D4 capsule pressure gauge safely measure?

A: This gauge is designed for non-corrosive gases and air. It should not be used with aggressive or corrosive gases that could affect the capsule or internal components.Q: When is it beneficial to select shatterproof glass instead of clear glass for the window?

A: Shatterproof glass is recommended in environments where physical impacts, vibration, or potential glass breakage could occur, providing additional safety and durability over standard clear glass.Q: Where should the pressure gauge be installed: bottom or center back connection?

A: The installation location depends on your panel or system layout. Bottom connections are suitable for direct or surface mounting, whereas center back connections are optimal for panel mounted applications, facilitating clear visibility and easy access.Q: What process is followed for calibration of the Standard Capsule Pressure Gauge Type D4?

A: Each gauge undergoes precise calibration against reference standards, ensuring reliable accuracy. A calibration certificate accompanies every gauge, validating its performance within 1.6% F.S. accuracy.Q: How is the protection class (IP52/IP65) relevant to my operating environment?

A: Protection class IP52 offers basic protection against dust and dripping water, suitable for most indoor settings. IP65 upgrades provide robust protection against dust and water jets, making the gauge ideal for more demanding or moist environments.Q: What benefits does the capsule element sensor offer over a Bourdon tube for low-pressure measurement?

A: The capsule element is highly sensitive to low pressures, making it more accurate and reliable for low-pressure gas or air applications, whereas Bourdon tubes are better suited for higher pressure ranges.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free