Welcome to Our Company -

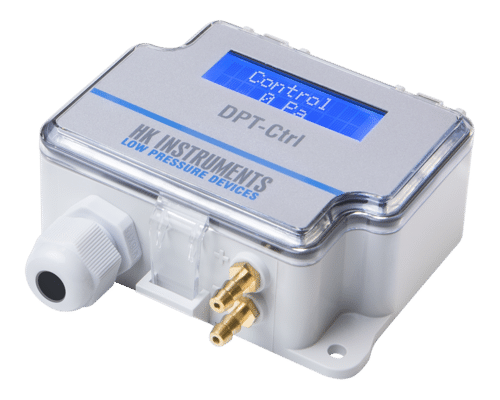

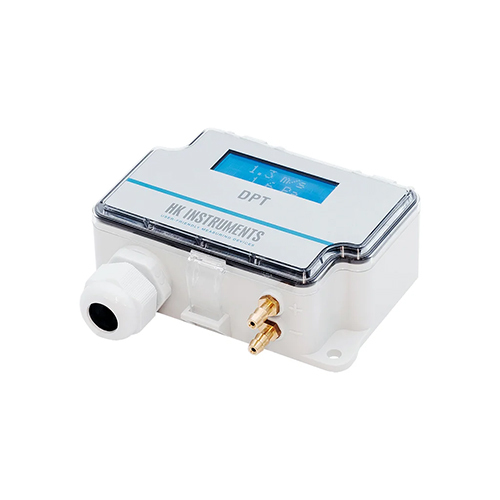

Differential Pressure Transmitter 988

Product Details:

- Outer Size 96 mm x 96 mm x 55 mm

- Thread 1/4 inch NPT Male

- Display 4-Digit LCD Display

- Sensor Type Capacitive Sensor

- Seal Material Silicone Rubber

- Grade Industrial Grade

- Material ABS Plastic Body

X

Differential Pressure Transmitter 988 Product Specifications

- Mounting Bracket, User Manual

- Air and Non-Corrosive Gases

- ABS Plastic Body

- 1/4 inch NPT Male

- 96 mm x 96 mm x 55 mm

- Panel Mount

- 4-Digit LCD Display

- 0 to 1000 Pa

- Powder Coated

- Capacitive Sensor

- Silicone Rubber

- 74 mm x 74 mm

- Industrial Grade

- 96 mm

- Polycarbonate

- Microprocessor-Based

- 1% F.S.

- -10C to +60C

- <1 sec

- 24V DC

- 150% of range

- Push-on tube connections for 6 mm ID tubing

- IP65 front

- Vertical

- 4-20 mA, 2-Wire

- Via front push buttons

Product Description

Applications :

- Building automation

- Measurement technology in the sanitary and industrial sector

- Differential pressure measurement between supply and return in heating systems

- Monitoring of filters, fans and compressors

- Cooling systems for heating / air conditioning

Technical Data :

- Pressure range

For an optimal adaptation to the application, different pressure ranges are available. The measurement is carried out by a ceramic pressure measuring cell, temperature-compensated via internal PTC.

- Output signal

In the 3-wire version there is an output signal of 0 10 V, or 4 20 mA available. For the 2-wire version the transmitter provides an output signal of 4 20 mA.

- Electrical connection

The electrical connection of the transmitter is optionally available with a 4-pin standardized device plug according to DIN EN 175301 Form A, or with a 4-pin M12 flange plug, A-coded, according to DIN EN 61079.

Precise Measurement and Output

The Differential Pressure Transmitter 988 ensures dependable and accurate readings, with a 1% full scale accuracy and a capacitive sensor that is ideal for air and non-corrosive gases. The microprocessor-based processing ensures stability and reliability, while the 4-20 mA output integrates seamlessly with industrial control systems. This makes it an essential component for automation and monitoring applications.

User-Friendly Features and Construction

Designed for straightforward setup and operation, this transmitter comes with front access zero and span adjustments and a bright, easy-to-read 4-digit LCD display. The powder-coated ABS housing, along with IP65 ingress protection at the front, offers durability in tough environments. Included accessories like a mounting bracket and user manual simplify installation and commissioning.

FAQ's of Differential Pressure Transmitter 988:

Q: How do I adjust the zero and span settings on the Differential Pressure Transmitter 988?

A: The zero and span adjustments can be made easily using the push buttons located on the front panel. This allows for quick calibration to ensure accurate measurement within your specific application range.Q: What is the recommended process for installing the Differential Pressure Transmitter 988?

A: For optimal performance, mount the transmitter vertically on a panel using the supplied mounting bracket. Connect the process tubing (6 mm ID) via push-on connections, and secure electrical wiring for the 4-20 mA output and 24V DC power supply as indicated in the user manual.Q: Where can the Differential Pressure Transmitter 988 be used?

A: This device is suited for industrial environments in India and globally, especially where accurate monitoring of air or non-corrosive gas pressure is needed. Typical applications include HVAC systems, clean rooms, and process automation.Q: What are the benefits of using a capacitive sensor in this transmitter?

A: The capacitive sensor offers high sensitivity, stability, and resistance to environmental variations, ensuring precise pressure measurements even in demanding industrial conditions.Q: How quickly does the transmitter respond to pressure changes?

A: The response time is less than 1 second, which ensures rapid and real-time updates of pressure readings. This is especially beneficial for applications where timely monitoring is critical.Q: When should I perform routine maintenance on the transmitter?

A: Routine maintenance, such as verifying calibration and inspecting process connections for leaks, is recommended at regular intervals based on your operational conditions. Always refer to the user manual for detailed maintenance guidelines.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free