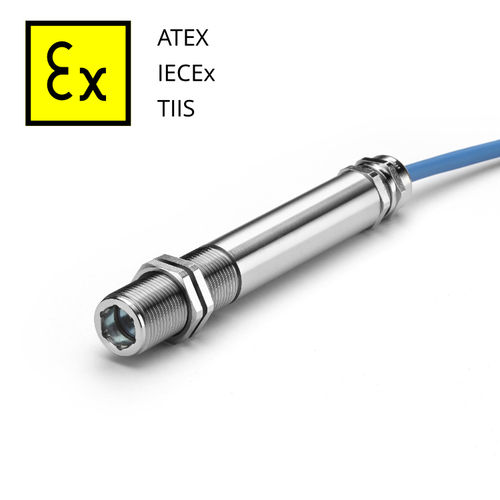

Infrared Temperature Sensor ExTemp

Product Details:

- Application Hazardous Area Temperature Measurement

- Power Consumption < 50 mA

- IP Rating IP65 (NEMA 4)

- Wireless No

- Sensitivity 0.02C

- Measurement Range -20C to 1000C

- Operating Temperature -20C to +70C

Infrared Temperature Sensor ExTemp Product Specifications

- -20C to +70C

- ATEX & IECEx Certified, Intrinsically Safe, Rugged Design

- Approx. 230 g

- Hazardous Area Temperature Measurement

- 1% of Reading or 1C (whichever is greater)

- Industrial Monitoring, Process Control

- < 50 mA

- IP65 (NEMA 4)

- No

- 0.02C

- -20C to 1000C

- 4-20mA, Two-wire

- Stainless Steel Housing

- 0.1C

- 3 m Cable (standard), extendable

- Infrared Temperature Sensor

- Non-contact Surface Temperature Measurement

- Infrared Radiation

- 24 VDC (typical)

- ExTemp Pyrometer

- Threaded (M20x1.5)

- 2-Wire System

- 240 ms

- Analog

- Adjustable, default 0.95

- Germanium

- Certified for Zone 0, 1, 2, 20, 21, 22 (Gas & Dust Environments)

- Pre-wired Cable

- 10% to 95%, non-condensing

- 8 to 14 m

- -30C to +85C

- Length 103 mm, Diameter 18 mm

Product Description

Specifications:- Temperature range: -20C to 1000C

- ATEX, IECEx and UKEX certified up to Zone 0 (gas) and Zone 20 (dust)

- Certified for use in Japan

- 4-20 mA output, two-wire, loop-powered

- Optional RS-485 network adapter and USB configuration tool

- Supplied with up to 25 m cable

- Cable may be extended even further (subject to safety requirements) cable runs could extend all the way back to the control room

- Stainless steel 316 housing, ideal for offshore applications

- Not designed or approved for fever detection

Hazardous Area Classification:

| Specification | Value |

|---|---|

| ATEX Classification | Ex II 1GD |

| IECEx Classification (Gas) | Ex ia IIC T4 Ga |

| IECEx Classification (Dust) | Ex ia IIIC T135C IP65 Da |

| Ambient Temperature Rating | -20C Ta 70C |

| Maximum DC Input Voltage | Ui = 28 V |

| Maximum Input Current | Ii = 93 mA |

| Maximum Input Power | Pi = 650 mW |

| Maximum Internal Capacitance | Ci = 8 nF |

| Maximum Internal Inductance | Li = 0 mH |

| ATEX Certificate Number | CML 14ATEX2079 |

| IECEx Certificate Number | IECEx CML 14.0032 |

| JapanEx Certificate Number | CML 23JPN2141 |

| UKCA Certificate Number | CML 21UKEX2001 |

General Specifications:

| Specification | Value |

|---|---|

| Temperature Range | Configurable from -20C to 1000C via optional USB adapter; pre-set to a choice of ranges between these limits (see Ordering) |

| Maximum Temperature Span | 1000C |

| Minimum Temperature Span | 100C |

| Output | 4 to 20 mA |

| Optional USB configuration tool and RS-485 network interface available | |

| Accuracy | 1C or 1%, whichever is greater |

| Repeatability | 0.5C or 0.5%, whichever is greater |

| Emissivity Setting Range | 0.20 to 1.00 (pre-set to 0.95) |

| Emissivity Setting Method | User configurable via optional modules |

| Response Time, t90 | 240 ms (90% response) |

| Spectral Range | 8 to 14 m |

| Supply Voltage | 12 to 24 V DC 5% |

| Maximum Current Draw | 25 mA |

| Maximum Loop Impedance | See Application Guide (available separately) |

Mechanical Specifications:

| Specification | Value |

|---|---|

| Construction | Stainless Steel 316 |

| Major Dimensions | 20 mm x length 150 mm (see Installation) |

| Mounting | M20 x 1.5 mm thread, length 46 mm, supplied with two mounting nuts |

| Cable Length | 5 m, 10 m, or 25 m as standard (custom lengths are also available) |

| Weight with 5 m Cable | 475 g |

Environmental Specifications:

| Specification | Value |

|---|---|

| Environmental Rating | IP65 (NEMA 4) |

| Ambient Temperature Range | 0C to 70C (Operating range) |

| Ambient Pressure Range | 80 kPa (0.8 bar) to 110 kPa (1.1 bar) |

| Relative Humidity | Max. 95% non-condensing |

| CE Marked | Yes |

| RoHS Compliant | Yes |

Unmatched Safety for Hazardous Applications

The ExTemp sensor is specifically engineered for environments where explosion protection is essential. With certifications for Zones 0, 1, 2, 20, 21, and 22, it ensures reliable operation in both gas and dust-laden atmospheres. Intrinsically safe design provides peace of mind in industries like petrochemicals, food processing, and pharmaceuticals.

Precision Monitoring & Control

Achieve superior process control with the ExTemp's high sensitivity (0.02C), fine 0.1C resolution, and swift 240 ms response time. Its adjustable emissivity accommodates diverse material surfaces, providing accurate readings across a range of -20C to 1000C, making it ideal for quality assurance and critical temperature monitoring.

Rugged, Reliable, and Easy to Integrate

Constructed from stainless steel and featuring an IP65-rated enclosure, the ExTemp withstands harsh industrial conditions. The pre-wired 3m cable (extendable) and threaded mounting (M20x1.5) simplify installation. The analog 4-20mA output integrates seamlessly into existing industrial control systems, enhancing reliability and ease of maintenance.

FAQ's of Infrared Temperature Sensor ExTemp:

Q: How does the ExTemp infrared temperature sensor operate in hazardous environments?

A: The ExTemp sensor is certified ATEX and IECEx for explosion protection, allowing safe operation in hazardous Zones 0, 1, 2 (gases) and 20, 21, 22 (dusts). Its intrinsically safe design minimizes ignition risk, making it suitable for monitoring temperature in potentially explosive atmospheres.Q: What materials and surfaces can the ExTemp accurately measure?

A: With adjustable emissivity (default 0.95), the ExTemp is versatile and can be calibrated for various surfaces, including metals, plastics, and painted or coated objects, delivering reliable non-contact temperature readings across industrial applications.Q: When should I use the ExTemp sensor over traditional contact sensors?

A: The ExTemp is ideal when surface temperatures need to be monitored without physical contact, especially where high temperatures, moving parts, or hazardous and inaccessible locations are involved, ensuring safety and efficiency.Q: Where can the ExTemp sensor be installed for optimal performance?

A: Install the sensor so it has a direct line-of-sight to the target surface within its measurement range. The rugged, threaded mounting (M20x1.5) allows secure attachment in areas exposed to moisture, dust, or high ambient temperatures (-20C to +70C).Q: What is the process for connecting the ExTemp sensor to my control system?

A: The ExTemp is supplied with a pre-wired 3m cable and outputs a standard 4-20mA analog signal through a two-wire connection, ensuring quick integration with most industrial monitoring and process control equipment. The cable can be extended for flexible installation.Q: How does using the ExTemp benefit my industrial process?

A: The ExTemp provides rapid, accurate surface temperature measurements without contact, reducing equipment wear and maximizing safety. Its robust construction, explosion-proof certification, and reliable performance enhance plant safety, process efficiency, and regulatory compliance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free