Welcome to Our Company -

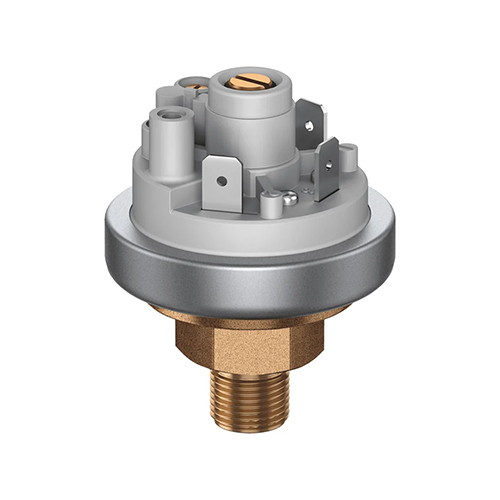

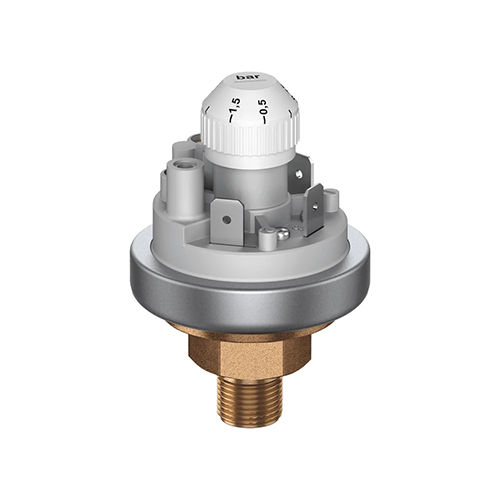

Pressure switch 901 EX factory-set

Product Details:

- Seal Material Nitrile rubber

- Bourdon Tube Not Applicable (Switch-based)

- Thread G1/4 or as per factory set specification

- Grade Industrial

- Sensor Type Electro-Mechanical

- Outer Size Approximately 75 mm x 75 mm

- Material Enclosure: Pressure die-cast aluminum; diaphragm: Nitrile rubber or as per set specification

X

Pressure switch 901 EX factory-set Product Specifications

- Flameproof / Explosion Proof Casting

- Mounting bracket and adjustment key

- Air, gases, non-corrosive liquids

- Enclosure: Pressure die-cast aluminum; diaphragm: Nitrile rubber or as per set specification

- G1/4 or as per factory set specification

- Nitrile rubber

- Not Applicable (Switch-based)

- 75 mm (approximate)

- 2% FS

- Direct Mounting

- Electro-Mechanical

- Factory set, typically 1 to 12 bar (customized as required)

- Industrial

- Pressure-operated switch

- Approximately 75 mm x 75 mm

- Suitable for clean air, gases, and non-corrosive fluids

- Industrial automation, hazardous area monitoring, compressor / pump protection

- IP65

- Factory set, tamperproof

- Snap action micro-switch

- SPDT / DPDT (as specified)

- Ex d IIC T6/ Flameproof to IS/IEC 60079-1

- Approx. 0.9 kg

- Compliant with PESO / CMRI / ATEX as specified

- 2 x 3/4" ET (as per IS 13947/IEC 947)

- 15A @ 250VAC, 10A @ 30VDC

- -10°C to +60°C

- Three terminal screw type

- Epoxy polyester powder coated

Product Description

Technical Data :

- Setting ranges:

Typ Factory-set switching points between Maximum positive working pressure

Standard/extended901.1x Ex 5 mbar and 200 mbar

200 mbar and 1.000 mbar0,5 / 4 bar

1 / 4 bar901.41Ex 500 mbar and 3.000 mbar 10 bar 901.51Ex 1,0 bar and 12 bar 25 bar 901.2x Ex -5 mbar and -200 mbar

-200 mbar and -900 mbar0,5 / 4 bar

1 / 4 bar901.30 Ex 5 mbar and 50 mbar 100 mbar

- Temperature range:

Temperature of media and ambient temperature from -20°C to 85°C

Storage temperature: -40° C bis +85° C

- Diaphragm material:

Depending on media NBR, Silicone, FKM (Viton®), EPDM. For 901.30 Silicone, others upon request.

- Pressure connection:

Material: PA, PVDF, Brass, Stainless steel

Hose nipple: 5,0mm, 6,5mm, 10,0mm

Thread: M10x1, G1/8, G1/4, G1/2

- Electrical rating:

24 VDC/100 mA

30 VDC/45 mA

- Electrical connection:

AMP flat plug 6.3 x 0.8 mm according to DIN 46244 or push-on screw terminals

- Protection class:

IP 54 (with cover 6371)

Reliable Flameproof Performance

Certified to Ex d IIC T6 standards and built to IS/IEC 60079-1 requirements, the Pressure Switch 901 EX is designed for hazardous area use, providing dependable protection in environments with potential explosive gases. Its rugged construction and epoxy polyester finish resist harsh industrial conditions, ensuring longevity and continued safety.

Tamperproof and Maintenance-Free

Thanks to its factory-set, sealed adjustment mechanism, the 901 EX pressure switch ensures set-point integrity and eliminates unauthorized access. This minimizes the risk of incorrect calibration during operation, making it a hassle-free solution for process automation, hazardous area monitoring, and equipment protection such as compressors and pumps.

Versatile Application Scope

This switch is compatible with various clean, non-corrosive mediums, including air and gases. Its direct mounting design, broad pressure scale range (1 to 12 bar), and IP65 ingress protection make it suitable for use across industries like chemicals, automation, and infrastructure where reliable monitoring is critical.

FAQ's of Pressure switch 901 EX factory-set:

Q: How is the Pressure Switch 901 EX installed and where can it be used?

A: The 901 EX is designed for direct mounting, typically via its G1/4" threaded connection, and comes with a mounting bracket. It is suitable for hazardous locations in industrial automation, hazardous area monitoring, and protection of compressors or pumps, meeting all relevant explosion-proof standards.Q: What ensures the explosion-proof safety of this pressure switch?

A: This device complies with Ex d IIC T6/Flameproof requirements per IS/IEC 60079-1. Its enclosure is made from pressure die-cast aluminum with an epoxy polyester powder coating, providing both mechanical strength and flameproof integrity for use in explosive atmospheres.Q: When should the Pressure Switch 901 EX be chosen over standard switches?

A: Select the 901 EX when you require reliable pressure monitoring in hazardous or explosion-prone areas that handle clean air, gases, or non-corrosive fluids. Its flameproof certification and tamperproof, factory-set adjustment make it ideal for safety-critical environments.Q: What types of electrical connections and switch contacts are available?

A: The switch is provided with three terminal screw-type connections and offers SPDT or DPDT snap-action contacts. It supports a maximum contact rating of 15A at 250VAC or 10A at 30VDC, ensuring compatibility with various industrial control systems.Q: How does the factory-set, tamperproof feature benefit users?

A: Factory calibration and a sealed adjustment prevent unauthorized changes to the pressure set point, enhancing both operational safety and repeatability. This approach removes the risk of accidental field misadjustment, particularly valuable in applications demanding compliance and process integrity.Q: Is this pressure switch suitable for all types of fluids?

A: It is engineered for clean air, gases, and non-corrosive fluids. The diaphragm is made from nitrile rubber or as per factory specifications, offering compatibility with standard industrial mediums-but it is not intended for aggressive, corrosive chemicals.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free