Welcome to Our Company -

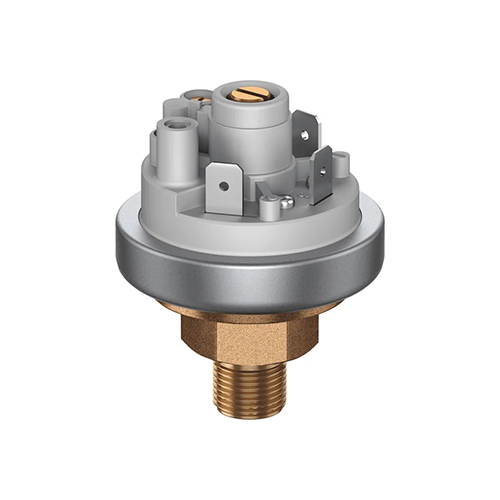

Pressure switch 901 factory-set

Product Details:

- Thread G1/4 (standard), other sizes available

- Seal Material NBR Rubber

- Sensor Type Electromechanical

- Outer Size Approx. 71 mm 32 mm 32 mm

- Grade Factory Set

- Display No

- Material Engineering Plastic and Brass

X

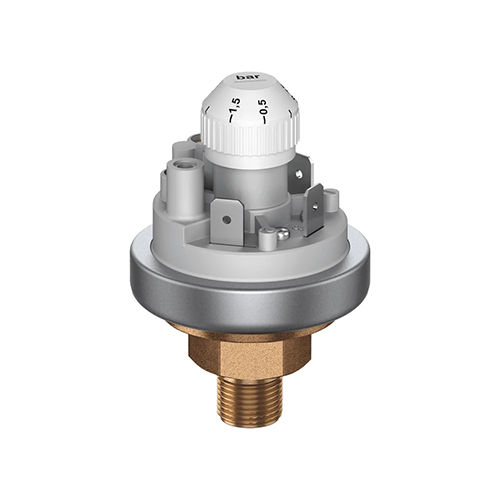

Pressure switch 901 factory-set Product Specifications

- 71 mm (Body dimension)

- Powder Coated/Enamelled

- Factory Calibrated

- G1/4 (standard), other sizes available

- 2 - 10 Bar

- Engineering Plastic and Brass

- Electromechanical

- NBR Rubber

- Surface/Panel Mount

- No

- Air, Water, Non-corrosive Fluids

- 2% of Full Scale

- Approx. 71 mm 32 mm 32 mm

- Factory Set

- Mouting Screws, Manual Included

- Manual and Automatic

- CE Certified

- IP44

- 1.5 Bar (Factory Set)

- -20C to +70C

- Impact-resistant Plastic

- Pressure control in compressors, booster pumps, water systems

- 16A 250V AC

- SPDT (Single Pole Double Throw)

Product Description

Applications :

- Wastewater technology

- liquid level measurement

- pump control

- medical technology

- and many more

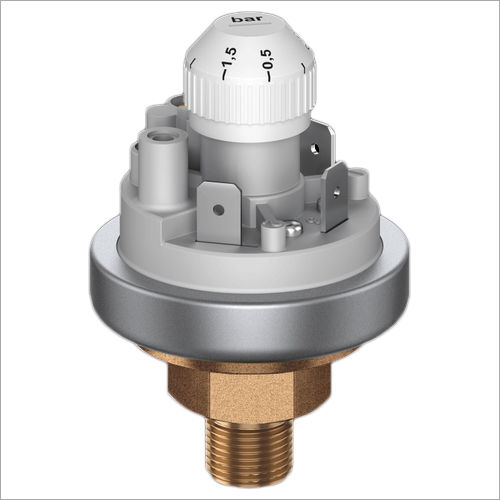

Technical Data :

Setting ranges:| Type | Factory-set switching points between | Maximum positive working pressure Standard/extended |

| 901.1x | 5 mbar and 200 mbar 200 mbar and 1.000 mbar | 0,5 / 4 bar 1 / 4 bar |

| 901.41 | 500 mbar and 3.000 mbar | 10 bar* |

| 901.51 | 1,0 bar and 12 bar | 25 bar |

| 901.2x | -5 mbar and -200 mbar -200 mbar and -900 mbar | 0,5 / 4 bar 1 / 4 bar |

| 901.30 | 5 mbar and 50 mbar | 100 mbar |

| *For pressure connections made of plastic, the maximum permissible working pressure is 7 bar! | ||

- Temperature range:

Ambient temperature from 20C to 85C

Temperature of media up to 85C or 130C depending on material of pressure connection and diaphragm.

- Diaphragm material:

Depending on media NBR, Silicone, FKM (Viton), EPDM. For 901.30 Silicone, others upon request.

- Pressure connection:

Material: PA, PVDF, PPS, Brass, Stainless steel

Hose nipple: 5,0mm, 6,5mm, 10,0mm

Thread: M10x1, G1/8, G1/4, G1/2

- Electrical rating:

Specification of the maximum values for ohmic load.

AgNi-contact:

6(1,5) A/250 VAC

2 A/24 VDC

Gilded contact:

100 mA/24 VAC

30 mA/24 VDC

On request AgNi contacts up to 10 A / 250 VAC can also be supplied.

- Electrical connection:

AMP flat plug 6.3 x 0.8 mm according to DIN 46244

- Protection class:

IP44 / IP54 / IP65 depending on the used protection cap

Versatile Pressure Control

This 901 Pressure Switch is designed for seamless integration into compressors, booster pumps, and water systems, offering dependable pressure regulation. Its factory-calibrated settings ensure reliability from installation without frequent readjustment. The device accommodates a wide range of non-corrosive fluids and operates efficiently within a scale of 2 to 10 bar, making it a versatile solution for industrial and residential water management.

Durable and User-Friendly Design

Built with impact-resistant engineering plastic and finished in powder coating or enamel, the Pressure Switch 901 delivers extended durability and resistance against harsh environments. The enclosure's IP44 protection safeguards the internal components from dust and water splashes, while the easy-to-install surface or panel mount offers convenience for professionals. The included manual and mounting screws help simplify the installation process.

Precision and Reliability

With a switching pressure differential of 1.5 bar and accuracy of 2% of full scale, the 901 Pressure Switch ensures precise control for air, water, and other non-corrosive fluids. Factory-set calibration, a robust brass-threaded connection, and CE certification highlight the device's safety and consistent performance, providing peace of mind for pressure management tasks.

FAQ's of Pressure switch 901 factory-set:

Q: How do I install the Pressure Switch 901 on my pump or compressor system?

A: The Pressure Switch 901 can be mounted on a panel or flat surface using the supplied mounting screws and manual. Its standard G1/4 thread ensures easy connection to most piping systems. Make sure to position the device where the enclosure is protected from direct water jets, and adhere to electrical safety standards during wiring.Q: What types of fluids can the 901 Pressure Switch measure and control?

A: This device is suitable for monitoring and controlling the pressure of air, water, and various non-corrosive fluids. The NBR rubber seal and engineering plastic/brass construction offer resistance to most standard media found in compressors and water systems. Avoid using with highly aggressive or corrosive chemicals.Q: When should I choose manual or automatic reset for this pressure switch?

A: Use the manual reset for applications requiring manual intervention after a pressure fault-ideal for safety-critical setups. Select automatic reset when you need the switch to return to operation automatically after pressure normalization, which is beneficial for uninterrupted system processes.Q: Where can the Pressure Switch 901 be deployed effectively?

A: This switch is ideal for industrial and commercial installations, including compressors, booster pumps, water supply systems, and HVAC units. Its compact, IP44-protected enclosure is best suited for indoor and sheltered outdoor environments, typical in pump houses, plant rooms, or factory settings.Q: What is the process for adjusting or recalibrating the switch?

A: The Pressure Switch 901 is factory-set for optimum performance with a pressure differential of 1.5 bar and scale range of 2-10 bar. While adjustments may not be necessary, consult the included manual if recalibration is required, or contact an authorized service provider for guidance, especially to maintain CE certification integrity.Q: How does using this pressure switch benefit my system's performance?

A: By maintaining accurate and consistent pressure control, the 901 Pressure Switch helps prevent equipment damage, improves efficiency, reduces downtime, and extends component life in your system. Its 2% full-scale accuracy and CE certification further ensure safe and reliable operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free